Quality

The SIGMA MOULDERS Quality Policy:

"Sigma Moulders will implement, monitor and continually improve our Quality Management System, ensuring we remain a preferred supplier of plastic injection molded components and assemblies.

Focusing on customer satisfaction we will meet or exceed our customer expectations for Quality, Delivery, Service and Value as related to our products or processes.

Quality objectives will be achieved through management commitment, employee empowerment and a team spirit of continuous improvement."

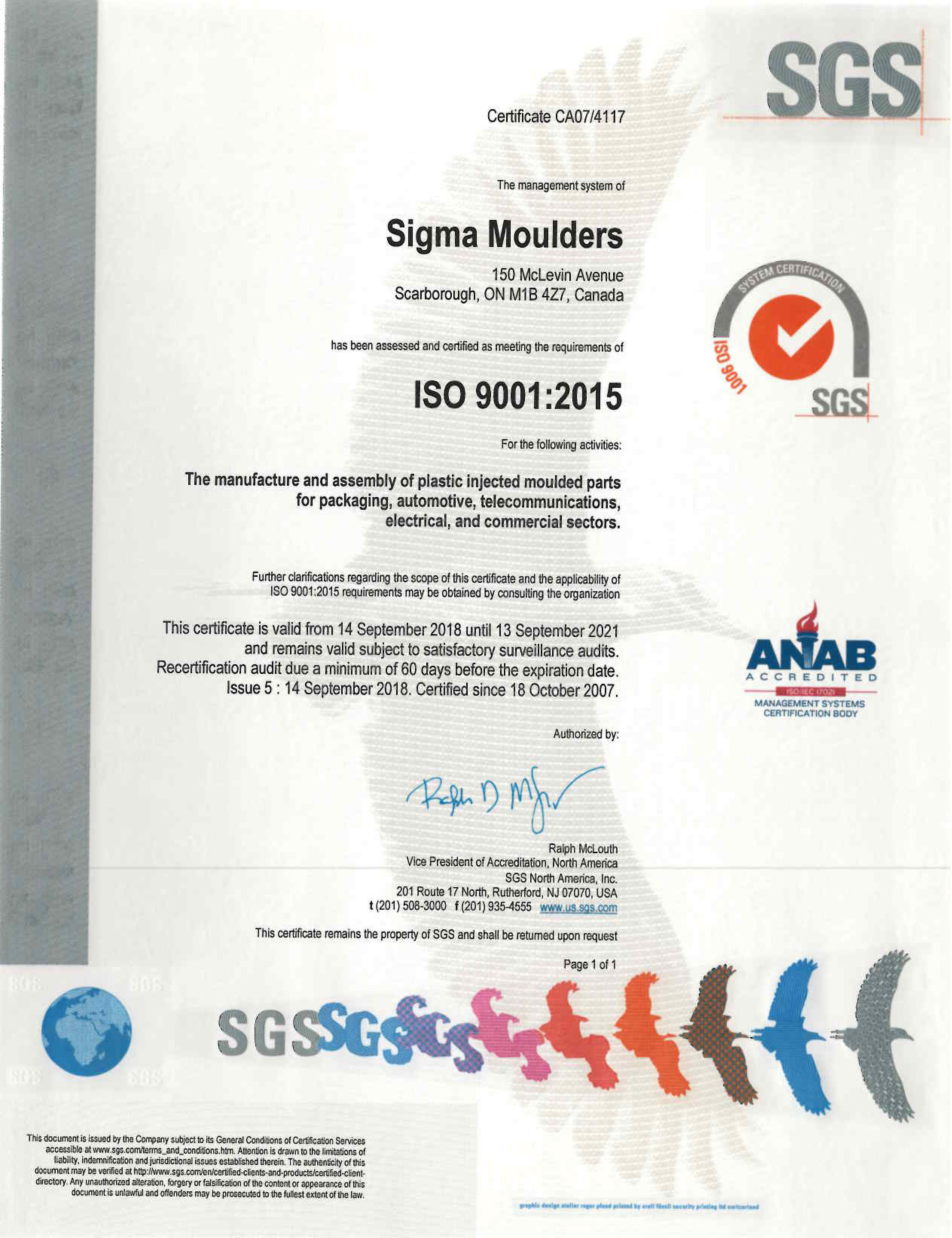

A quality manufacturing process ensures a quality product. As a IATF-16949:2016 and ISO 9001:2015 certified company, our processes and systems are clearly defined, followed and are continually improved. SIGMA MOULDERS utilizes a defect prevention philosophy, proactive problem solving and statistical analysis of internal and external metrics, including goals of 0% defects and 100% on-time delivery, to drive continual improvement throughout our company.

Our Quality Assurance Team uses Statistical Process Control (SPC), Coordinate Measuring Machine (CMM) and other measurement systems to ensure that all measurements - from layout to hourly in-process checks - are accurate.

SIGMA MOULDERS supports and practices Advanced Product Quality Planning (APQP) facilitated by a cross-functional team consisting of, but not limited to, Quality, Engineering, Production and Purchasing. Each new customer program goes through the APQP process which consists of thorough review and evaluation of the program requirements, part and mold design, sampling process and production efficiency.

|

|